Injection mold is a common manufacturing tool mainly used for manufacturing plastic injection molded products.

It is composed of high-precision molds and mold supports, used to manufacture plastic products of various shapes and sizes, such as plastic cups, plastic plates, plastic toys, automotive parts, etc.

In injection molding, the mold is injected into melted plastic and then solidified through a cooling process to form the desired plastic product.

Injection molds play a crucial role in modern manufacturing.

The design and manufacturing of injection molds require a high level of precision and technical expertise.

This is because injection molded plastic products must meet precise size and shape requirements, and must have high-quality surface and dimensional accuracy.

If the precision of the mold is insufficient, it will lead to dimensional deviations, surface roughness, damage, and other problems in the produced plastic products, which will affect product quality and production efficiency.

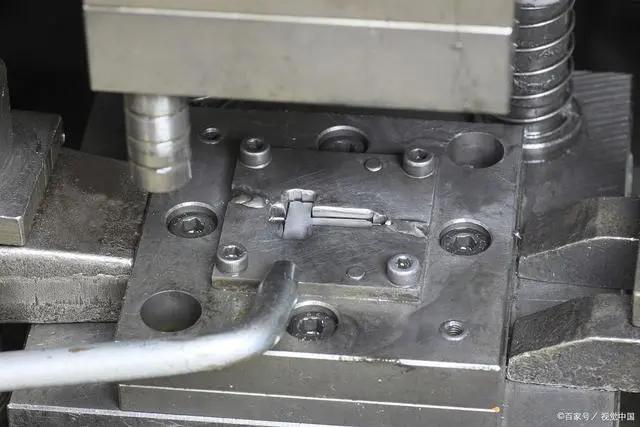

Injection molds typically consist of two main parts: the mold and the mold support.

A mold is a steel block with a hollow cavity, providing a space of the desired design shape and size for the product.

Molds are usually made of high-quality steel and undergo multiple precision machining processes to ensure a smooth and even surface, as well as a very high degree of precision in fitting with other mold parts.

The mold bracket is used to support and maintain the shape of the mold.

Mold supports are usually made of steel and aluminum alloys, with strong rigidity and stability to maintain the correct position and shape of the mold.

The mold bracket must also be able to withstand the enormous pressure and vibration required for high-pressure injection molding processes.

The manufacturing process of injection molds is a complex project that requires multiple different process steps.

Firstly, it is necessary to conduct mold design and manufacturing planning, and determine the required materials and tools.

Then, according to the design drawings and specifications, precision machining and assembly are carried out.

The manufacturing process includes machining, fitter, heat treatment, electrical discharge machining, grinding, and polishing.

The manufacturing process requires advanced technology and precision machining equipment, such as high-precision machine tools, CNC machining centers, wire cutting machines, CNC grinders, etc.

In the injection molding process, injection molding tools play a crucial role.

Firstly, the grinding tool must be placed into the injection molding machine and the plastic must be melted by heating.

Then, the melted plastic is injected into the cavity of the grinding tool through high pressure.

Next, the melted plastic is solidified by cooling and formed into the desired plastic product in the mold.

Finally, by opening the mold of the injection molding machine, the molded plastic product is removed from the mold.

Injection molds have many advantages.

Firstly, it can produce high-precision, high-quality, and complex plastic products.

Secondly, the injection molding process is faster and more efficient than other molding techniques, which can greatly improve production efficiency.

In addition, the injection molding process can also achieve automated production, reducing labor costs and human errors.

Injection molds are widely used in many different fields, such as automobiles, medical devices, electronics, home appliances, aerospace, etc.

In the automotive manufacturing industry, injection molding tools can be used to manufacture automotive components such as door handles, instrument panels, seats, etc.

In the field of medical devices, injection molds can be used to manufacture medical devices such as syringes, infusion sets, surgical instruments, etc.

In the field of electronics, injection molds can be used to manufacture electronic product casings, such as phone casings, computer casings, etc.

In short, injection molds are one of the indispensable tools in modern manufacturing industry.

It can manufacture high-quality, high-precision, and complex plastic products, and can achieve efficient automated production, improving production efficiency and reducing costs.

With the continuous advancement of manufacturing technology and the continuous development of injection molds, injection molding technology will be applied in a wider range of fields.