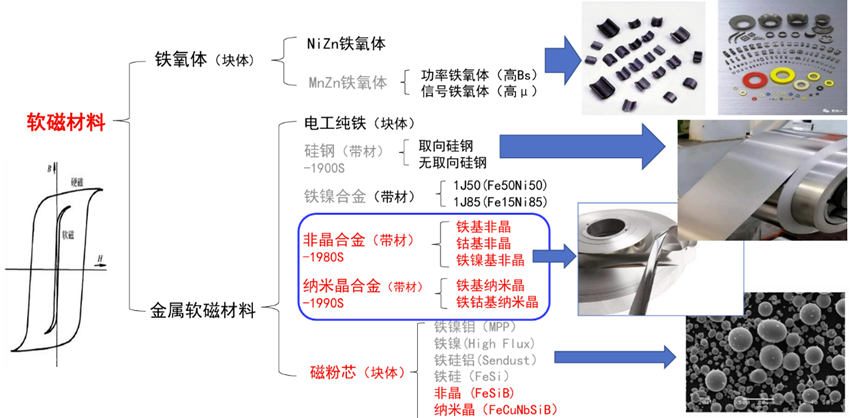

A、 Classification and Application of Commonly Used Soft Magnetic Materials

Soft magnetic materials are one of the basic materials in industries such as power electronics and information electronics, with special functions of magneto electric conversion.

They are widely used in fields such as electric energy conversion, electromagnetic interference resistance, wireless charging, and near-field communication.

They have a large number of applications in industries such as new energy vehicles, new energy power generation, consumer electronics, industrial electronics, communication, cloud services, computers, and aerospace.

Figure 1 Common Soft Magnetic Materials

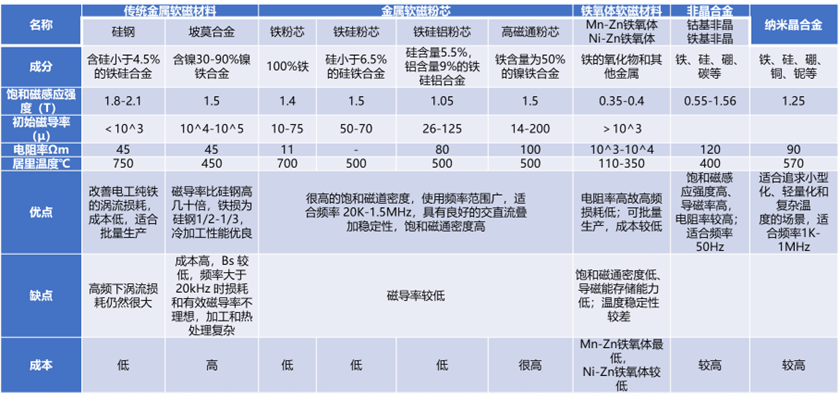

Soft magnetic ferrite is still the largest scale soft magnetic material currently available, which is a ferromagnetic oxide mainly composed of Fe2O3.

It can be divided into various categories such as manganese zinc, nickel zinc, etc. according to formula differences.

In terms of performance,

it can be divided into power soft ferrite materials (used for energy conversion/analog electric range) and high permeability soft ferrite materials (used for electromagnetic compatibility, signal transmission/digital electric range).

Silicon steel sheets are divided into hot-rolled silicon steel and cold-rolled silicon steel according to production processes.

Cold rolled silicon steel is divided into cold-rolled non oriented silicon steel and cold-rolled oriented silicon steel, and is the main material for manufacturing iron cores of generators, motors, and transformers.

Metal alloy soft magnetic powder refers to powders containing iron, silicon, and other metal or non-metal elements,

including iron silicon magnetic powder, iron silicon aluminum alloy magnetic powder, iron silicon chromium magnetic powder, iron nickel magnetic powder, etc.

Metal alloy soft magnetic powder can be further processed into magnetic cores, mainly used for making power inductance components.

The types of amorphous alloys mainly include iron-based, iron nickel based, and cobalt based amorphous alloys.

Nanocrystalline ultra-thin tapes have advantages such as high saturation magnetization, low coercivity, high initial magnetic conductivity, and high Curie temperature rate.

Their comprehensive soft magnetic properties are superior to ferrites, which can reduce the volume of magnetic devices, lower magnetic device losses, and improve efficiency.

They can be used in common mode inductors, electronic transformers, and other fields.

Table 1 Comparison of commonly used soft magnetic materials

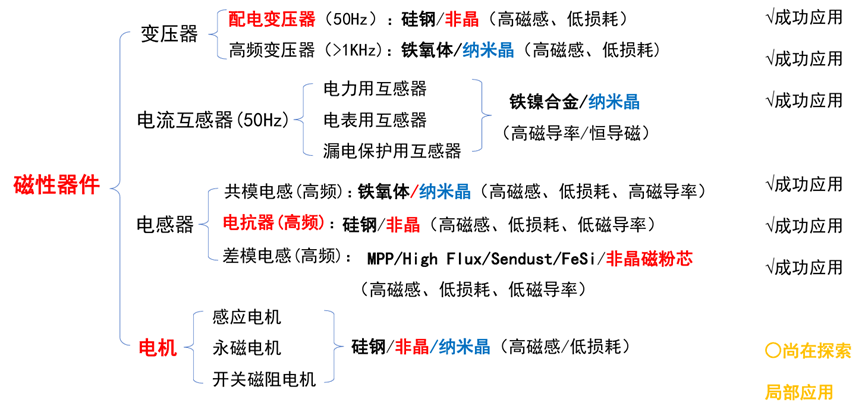

B、 Classification and Application of Commonly Used Magnetic Devices

Magnetic devices are electronic components based on Faraday's law of electromagnetic induction, consisting of magnetic cores, wires, bases, and other components, which achieve the mutual conversion of electrical and magnetic energy.

They are an important branch of the electronic components industry. Mainly including electronic transformers, inductors, etc.

A transformer is an electronic component that uses electromagnetic induction to achieve the function of AC voltage rise and fall or impedance transformation, consisting of an iron core (or magnetic core) and coils.

Inductors are passive electronic components that can store electrical energy in magnetic form, and are one of the basic passive components in electronic circuits. They are divided into traditional plug-in inductors and chip inductors.

Amorphous alloys have been successfully applied in distribution transformers, reactors (high-frequency), etc.,

while nanocrystalline alloys have been successfully applied in high-frequency transformers, current transformers, common mode inductors, etc.

The application of amorphous and nanocrystalline alloys in motors is still under exploration.

Figure 2 Common magnetic devices

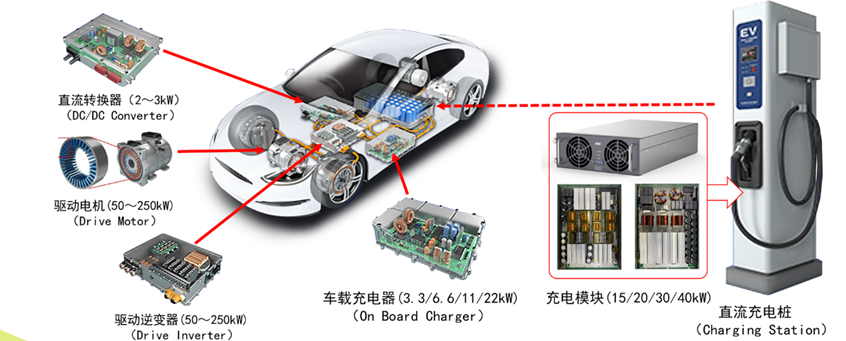

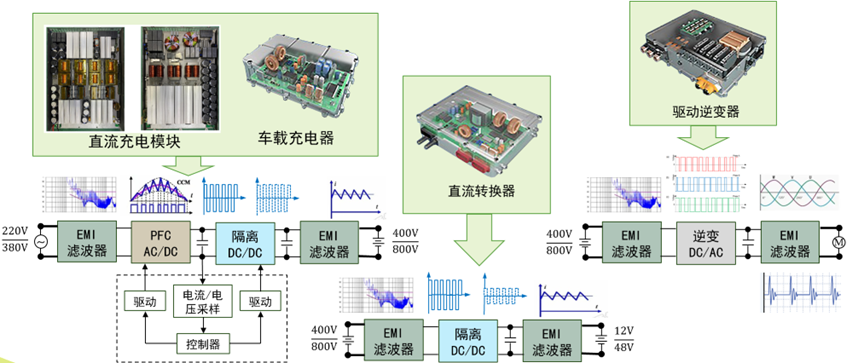

In addition to traditional components such as vehicle control unit (VCU), body EMI, low-frequency antenna, combination instrument, head up display, intelligent interior rearview mirror, electronic clock, display screen,

as well as some controllers, sensors, cameras and other applications, soft magnetic materials and devices are widely used in new energy vehicle components such as DC charging piles,

on-board charging machine (OBC), on-board DC/DC converters, high-voltage distribution box (PDU), and drive motor systems.

Figure 3: The extensive application of soft magnetic materials and devices in new energy vehicle components

New energy vehicles integrate a large number of soft magnetic components, such as common mode and differential mode inductors in EMI filters, PFC inductors in PFC circuits,

resonant inductors in DC/DC circuits, high-frequency transformers, DC filter inductors, etc., and are developing towards high frequency and high power.

Figure 4: The extensive application of soft magnetic materials and devices in high-voltage circuits of new energy vehicles

C、 Development history and market situation of amorphous soft magnetic alloys

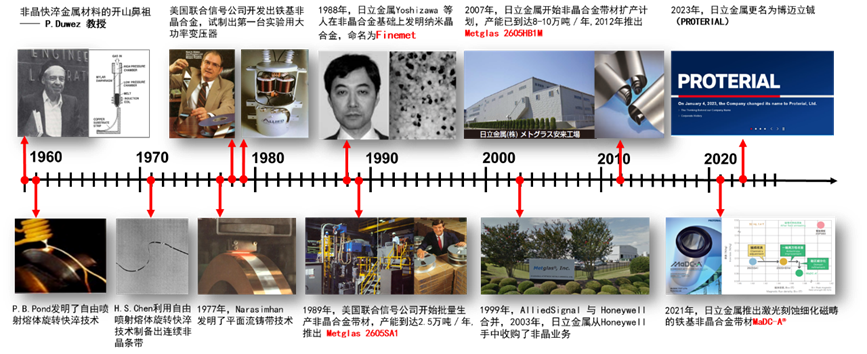

Since Professor Duwez invented the rapid quenching process to prepare amorphous alloys in the United States in 1960, the development of amorphous soft magnetic alloys has generally gone through two stages: the first stage to 1988.

In 1984, four transformer manufacturers in the United States showcased practical amorphous distribution transformers at the IEEE conference, marking the peak of the first stage.

In 1989, Allied Signal Company in the United States had an annual production capacity of 25000 tons of amorphous strip, and about one million amorphous distribution transformers were put into operation worldwide.

Almost all of the iron-based amorphous strip used came from the company.

Starting from 1988, the development of amorphous materials entered its second stage, with a landmark event being the development of Finemet, a nanocrystalline soft magnetic alloy, by Yashiwa et al.

from Hitachi Metals in Japan through crystallization treatment on the basis of amorphous alloys.

That year, Hitachi Metals' nanocrystalline alloys were industrialized.

Figure 5 Development history of amorphous soft magnetic alloys abroad

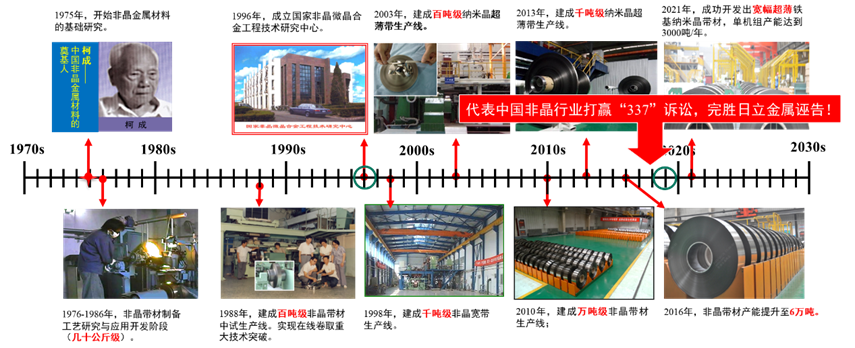

The research on amorphous materials in China began in 1975.

The National Science and Technology Commission has included the research, development,

and industrialization of amorphous and nanocrystalline alloys in major scientific and technological projects for five consecutive five-year plans since the "Sixth Five Year Plan".

The landmark achievements include: the construction of a pilot production line for 100 ton amorphous strip during the Seventh Five Year Plan period, with a strip width of 100mm;

During the "Eighth Five Year Plan" period, breakthroughs were made in the online automatic winding technology of amorphous strip materials, and a trial production line with an annual output of 200000 amorphous iron cores was built;

During the Ninth Five Year Plan period, the National Engineering Technology Research Center for Amorphous Microcrystalline Alloys was established, and a thousand ton level amorphous strip production line was built with a strip width of 220mm.

At the same time, an annual production line of 600t amorphous distribution transformer iron cores was established.

Through the implementation of the first four five-year science and technology research and development plans, China has basically achieved the industrialization of amorphous alloy strips and products.

According to the 2021 Metallurgical Science and Technology Award selection results from the China Iron and Steel Industry Association and the Society of Metals,

the "Engineering Technology Development and Application of Wide Width Ultra Thin Iron based Nanocrystalline Strip" project, jointly completed by six domestic units including Antai Technology and Qingdao Yunlu, has been successful.

The newly developed continuous production equipment and manufacturing process for ultra-thin nanocrystalline strip have filled the domestic technological gap.

Figure 6 Development history of amorphous soft magnetic alloys in China (Steel Research Institute China Steel Research Group Antai Technology)

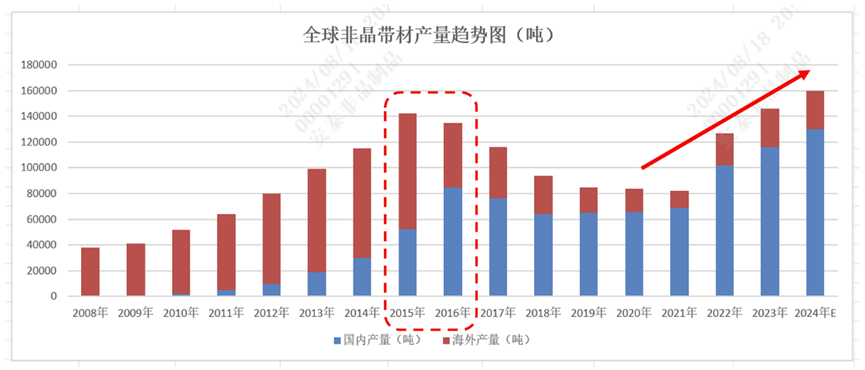

The production of amorphous tapes at home and abroad reached a peak in 2015, and the production of domestically produced amorphous tapes surged after 2016;

Subsequently, as the number of bidding for distribution transformers in the power grid decreased, the amount of amorphous strip decreased for several consecutive years;

Starting from the second half of 2021, due to the rise in prices of oriented silicon steel and the promotion of three-dimensional coil transformers,

the demand for amorphous strip has gradually rebounded, and market driven production has gradually recovered.

The future growth trend will continue.

At present, Hitachi Metals is in a leading position globally, with major domestic enterprises including Antai Technology, Yunlu Co., Ltd., Zhongyan Amorphous, Zhaojing Technology, Jiangsu Guoneng, Henan Zhongyue, etc.

Figure 7 Global amorphous strip production

D、 Characteristics, preparation process and application of amorphous soft magnetic alloy materials

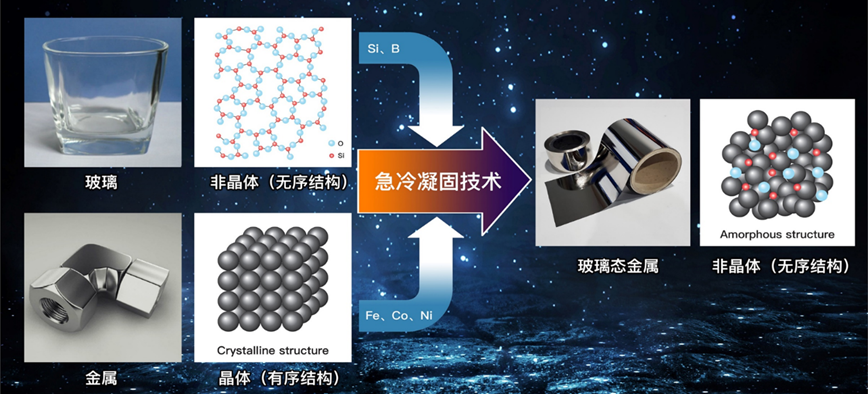

Amorphous alloy, also known as "liquid metal or metallic glass",is mainly produced by rapidly cooling the alloy melt at a rate of millions of degrees per second using rapid cooling technology to obtain an amorphous alloy thin strip with a thickness of about 0.03mm.

Its physical state is characterized by long-range disordered amorphous arrangement of metal atoms.

Thanks to the special atomic structure formed by the extreme production process mentioned above, amorphous alloys have good properties such as low coercivity, high magnetic permeability,

and high electrical resistivity compared to traditional materials such as silicon steel.

Figure 8 Characteristics of amorphous alloy materials

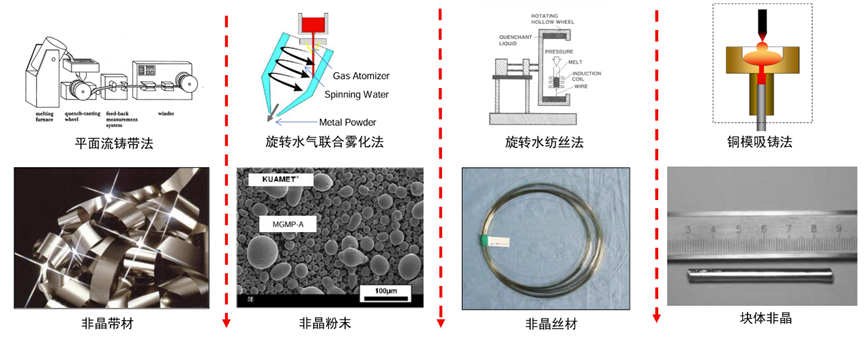

In addition to amorphous strips, there are currently other product forms of amorphous alloys such as powders, wires, blocks, coatings, etc.

Figure 9: Morphology of Amorphous Alloy Products

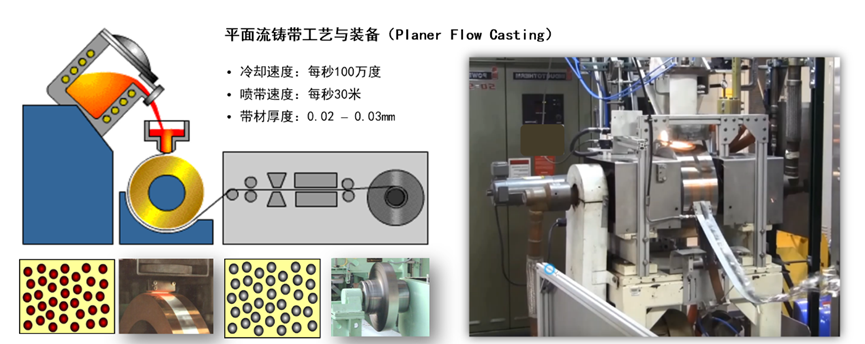

The planar flow casting process of amorphous strip adopts rapid solidification technology, which melts the mother alloy and sprays it onto a high-speed rotating cooling roller through a nozzle, instantly cooling to form a thin strip like paper.

There are several characteristics:

1. Fast cooling rate: The temperature of liquid alloy is basically between 1400-1500 ℃, and it instantly solidifies to near room temperature, with a cooling rate of millions of degrees per second;

2. Fast spraying speed: 30m/s is like the speed of a bullet just flying out, and it is very difficult to catch objects that are close to the speed of the bullet;

3. Thin thickness: The thickness of the sprayed strip is 20-30 μ m, and precision control is mainly achieved through the design of the slit under the nozzle package and the spacing between the roller nozzles.

Figure 10 Plane Flow Casting Process and Equipment

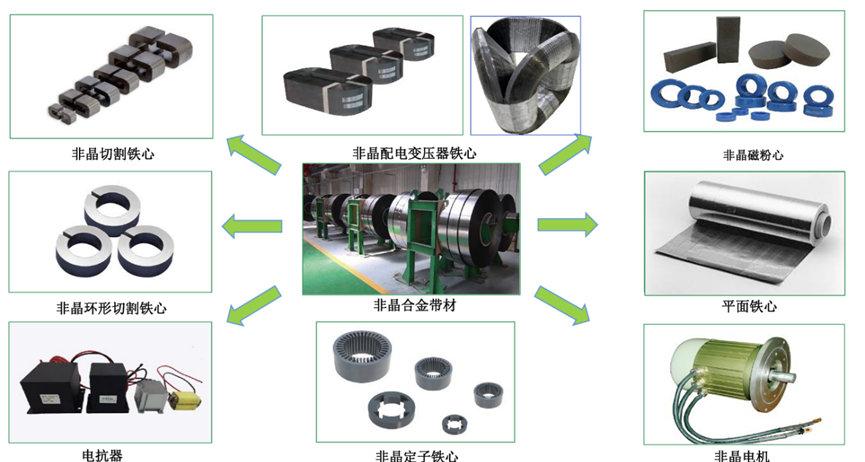

The types of amorphous alloys mainly include iron-based, iron nickel based, and cobalt based amorphous alloys. Iron based amorphous alloys are widely used in energy-saving distribution transformers;

The application range of iron nickel based amorphous alloys corresponds to that of nickel perovskite alloys, but they are superior in energy loss and mechanical strength, and are used in leakage switches, magnetic shielding, etc.

Cobalt based amorphous alloys have the highest magnetic permeability among amorphous alloys, and have excellent wear resistance and corrosion resistance. They are used in transformers, inductors, etc.

in military power supplies with strict requirements, and can replace perovskite alloys, ferrites, etc. The typical application scenarios of iron-based amorphous materials are shown in the following figure.

Figure 11 Typical application scenarios of iron-based amorphous materials

E、 Application of iron-based non alloy in drive motors

The material of the stator and rotor iron core is the key to determining the performance of the drive motor.

Currently, mass-produced drive motors mainly use high-grade non oriented silicon steel for power energy conversion.

In China, low grade non oriented silicon steel is mainly used. With the trend of new energy vehicle drive motors, large motors,

and energy-saving motors in the future, the demand for high-grade non oriented silicon steel is expected to continue to grow.

China has gradually shifted from using 0.35mm materials in large quantities to 0.27-0.30mm products, with individual batches using 0.20mm and 0.25mm products.

There are various technical routes for high-performance iron core materials, including 6.5% Si high silicon steel (also known as super silicon steel), cobalt iron alloy, nickel iron alloy, amorphous materials, etc.

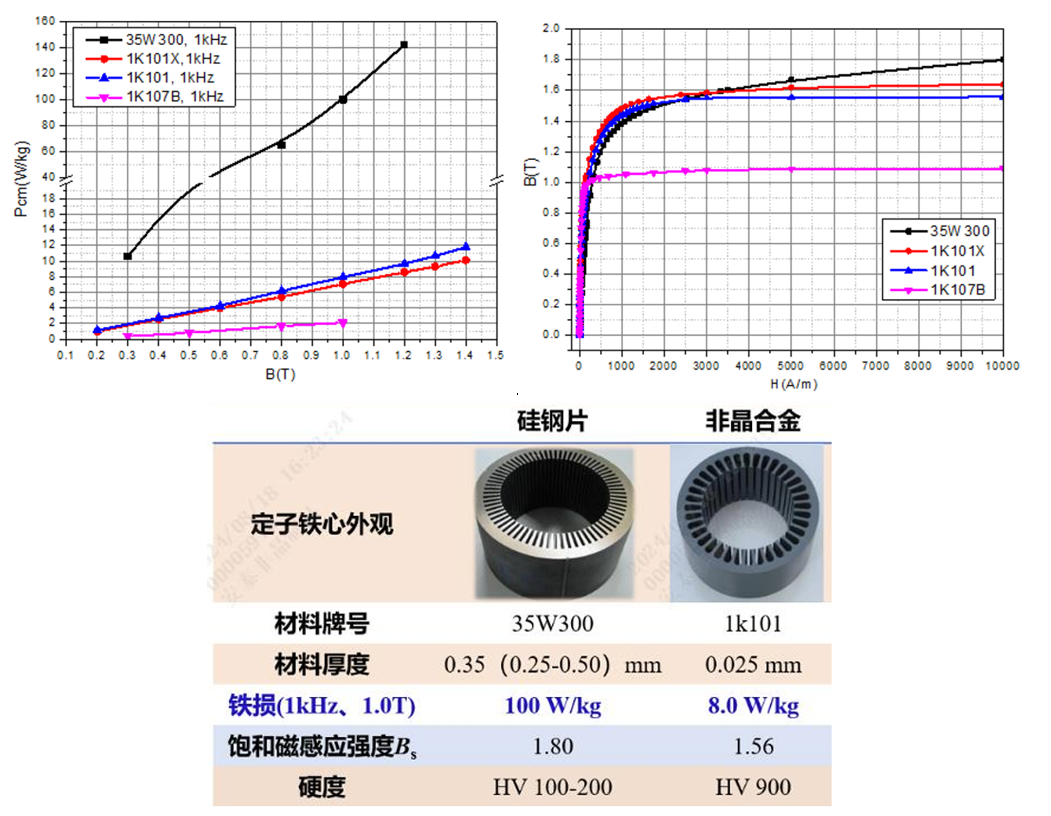

At 1kHz and 1T conditions, the unit loss of iron-based amorphous motors is only 1/10 of that of traditional silicon steel.

The iron loss of amorphous stator motors is reduced by more than 50% -70% compared to silicon steel motors, which is suitable for the high-frequency, high-speed and high-efficiency development trend of new energy vehicle main drive motors.

At present, the saturated magnetic induction of amorphous materials is lower than that of non oriented silicon steel.

The peak torque and motor volume of amorphous motors still have a gap compared to silicon steel motors,

and the motor design and material performance need to be further improved and optimized. In addition, amorphous stator processing technology is still a bottleneck in industrialization technology,

and multi-layer amorphous strip composite bonding technology and stamping technology for ultra-thin superhard materials are expected to break through.

Figure 12 Performance comparison between amorphous alloy and silicon steel sheet